Capacitive Discharge Ignition (CDI) Circuit is like small engine lighter.

It keeps power like balloon and then release fast boom!

Make strong spark to burn fuel.

This type of circuit are used in bike, cutter and old car.

Circuit Working:

Parts List:

| Category | Item | Quantity |

|---|---|---|

| Resistors | 100Ω 1W | 1 |

| 56Ω 1W | 1 | |

| Capacitors | PPC 105 400W | 1 |

| Semiconductors | SCR BT151 | 1 |

| Diodes 1N4007 | 3 | |

| Ignition coil | 1 | |

| High tension wire to spark plug | 1 |

This post show an easy way to make CDI (Capacitive Discharge Ignition) system using normal ignition coil and SCR circuit.

Ignition system is important but make spark to burn fuel and start engine.

Old cars use breaker for this job.

Now most cars use better system which are called CDI.

How CDI Work:

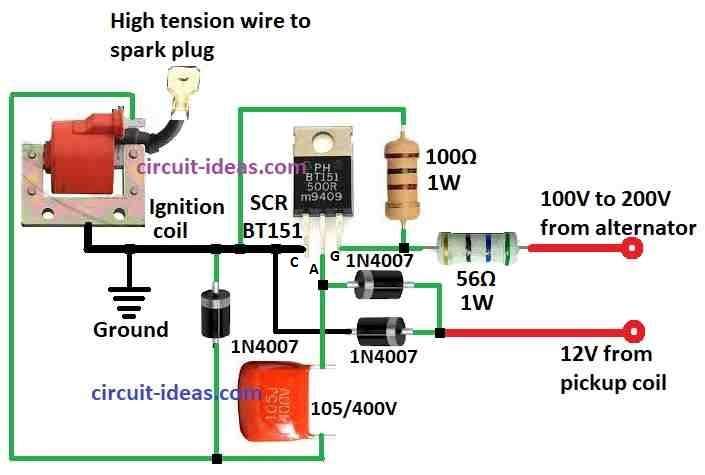

CDI take two power signals:

- One big voltage with 100 to 200V AC which come from alternator

- One small voltage with 10 to 12V AC which come from pickup coil

Big voltage changes to DC and charge the capacitor.

Small voltage hit the SCR and SCR opens and send power from capacitor to ignition coil.

Ignition coil boost power to very high voltage and send to spark plug.

Spark plug make spark and with this the engine start.

Why CDI Good:

Alternator does not gives enough power alone.

CDI keep power and releases fast and makes strong spark.

Ignition coil work like transformer and make voltage bigger.

CDI help engine run better and to start easily.

Formulas:

To make a high voltage spark a CDI circuit stores power in a capacitor and then quickly sends it through the ignition coil.

Basic formulas to understand:

1. Charging the Capacitor:

Voltage across capacitor over time:

Vc(t) = Vs * (1 – exp(-t / (R * C)))

- Vs is the power supply voltage

- R is the resistance

- C is the capacitance

- exp is the exponential a math function

2. Energy Stored in Capacitor:

E = 0.5 * C * V²

- E is the energy

- C is the capacitance

- V is the voltage

3. Voltage in an Inductor (like ignition coil):

Vl = L * (di/dt)

- Vl is the voltage across inductor

- L is the inductance

- di/dt is how fast current is changing

Note:

If we understand these formulas we can design our own CDI circuit.

We can change the values of components like resistors, capacitors and coils based on what we need our circuit to do.

How to Build:

To build a Capacitive Discharge Ignition CDI Circuit follow the below mentioned steps:

- Connect SCR cathode to ground.

- Put one 1N4007 diode between ground and capacitor 105 400V.

- Join two 1N4007 diodes in line series from ground to SCR anode.

- Put 100 ohm resistor between SCR gate and ground.

- Connect one side of 56 ohm resistor to SCR gate and other side to high voltage AC from alternator.

- Connect one side of capacitor 105 400V to SCR anode and other side to primary wire of ignition coil.

Conclusion:

Capacitive Discharge Ignition (CDI) Circuit is smart circuit for make strong spark to start a engine.

It gives more hot spark, better work and easy start than old system.

But it is little hard and can damage easily, so it is better for bike and small engine only.

References:

Low-Cost Automotive Capacitive Discharge Ignition (CDI) Coil for Low Frequency Ozone Generator

Leave a Reply