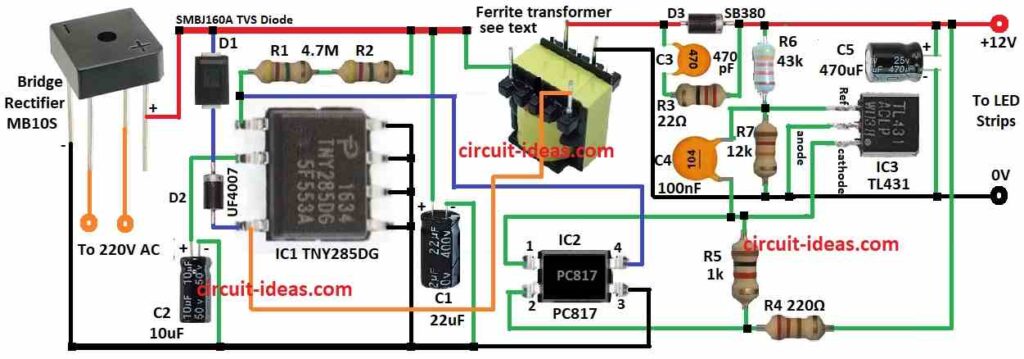

12V SMPS driver change big AC power from 110V or 220V into small 12V DC.

Circuit is good for LED strip light.

In this DIY we make cheap and strong LED driver.

It can power full 12V LED strip with 100 or 200 LEDs.

Important points to follow:

Circuit uses 230V AC direct which is very dangerous.

Only safety is at short-circuit protection at output.

If we want to make SMPS then first learn well and follow trusted diagram and take safety care.

Only try if having good skill and knowledge in electronics.

Circuit Working:

Parts List:

| Component Type | Description | Quantity |

|---|---|---|

| Resistors (All resistors are 1/4 watt unless specified) | ||

| 4.7M | 2 | |

| 22Ω | 1 | |

| 220Ω | 1 | |

| 1k | 1 | |

| 43k | 1 | |

| 12k | 1 | |

| Capacitors | ||

| Ceramic 470pF 200V | 1 | |

| Ceramic 100nF 50V | 1 | |

| Electrolytic 22μF 400V | 1 | |

| Electrolytic 10μF 50V | 1 | |

| Electrolytic 470μF 25V | 1 | |

| Semiconductors | ||

| IC TNY285DG | 1 | |

| IC PC817 | 1 | |

| IC TL431 | 1 | |

| SMBJ160A TVS diode | 1 | |

| UF4007 diode | 1 | |

| SB380 schottky diode | 1 | |

| Bridge Rectifier MB10S | 1 | |

| Transformer Ferrite core (see specific requirements) | 1 |

First learn how LED strip driver work and its parts.

Circuit is high voltage so we need to keep in strong box for safety.

For learning we have made a simple test on veroboard with no solder.

C1 feedback capacitor control output voltage.

TNY285DG main IC drives transformer and switch 125 kHz.

C2 supply capacitor keeps IC smooth.

R1, R2 are under voltage lockout and they stop IC if input low.

D1, D2 protect IC from spikes.

D3 Schottky SB380 rectify and control current and snubber R3 and C3 protect D3.

C5 output capacitor keeps LED power steady.

PC817 optocoupler isolate high voltage from low to do feedback.

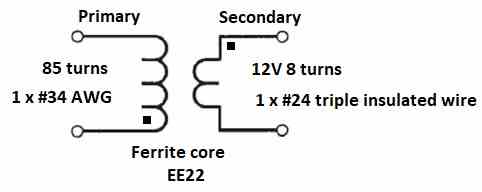

Transformer Construction:

Steps to Make Transformer:

Start winding 85 turns from pin 2 and use 34 AWG single wire with double coated.

Wind clockwise left to right.

Second layer wind right to left.

Next layer clockwise again.

Last layer spread wire evenly and finish at pin 1.

Use 3 layers polyester tape 1 mil and 8.45 mm wide.

Start pin 7 and wind 8 turns 24 AWG triple insulated single wire clockwise.

Spread evenly and finish at pin 6.

Add 2 layers tape over windings.

Put core halves together tight.

No vacuum dip is needed just varnish evenly.

Formulas:

Important Formulas for Designing 12V SMPS Driver for LED Strip with ICs:

1. Turns Ratio (Np/Ns):

Np/Ns = √[Vout∗(Vin−Vout)]/[Vin∗f∗Ae]

where,

- Np is in primary turns

- Ns is in secondary turns

- Vin is the input voltage for 12V

- Vout is the output voltage for 12V

- f is the frequency in kHz

- Ae is the cores effective area

2. Peak Primary Current (Ipeak):

Ipeak = Vin∗Dmax/(f∗Ae)

Dmax = Max duty cycle

Use this to find highest current in primary winding.

3. Output Capacitor (Cout):

Cout≥Iout∗(1−D)/(f∗ΔVout)

where,

- Iout is the output current

- D is the duty cycle

- ΔVout is the ripple voltage at output

This helps to choose the right capacitor.

4. Feedback Voltage Divider:

Vout / Vref = Rtop / Rbottom

where,

- Vref = The TL431s reference voltage, which is usually 2.5V.

5. Efficiency (η):

η = Pout / Pin × 100%

where,

- Pout is the output power

- Pin is the input power

How to Build:

To build a 12V SMPS Driver Circuit for LED Strip follow the below mentioned steps for connections:

- Get all parts shown in circuit diagram.

- Pin 1 connect to (+) supply through R1 and R2

- Pin 2 connect to GND through C2

- Pin 4 connect to (+) supply through D1 and D2

- Pins 5, 6, 7, 8 connect all to GND

- Connect from (+) supply to GND

- IC2 pin 1 connects to cathode of IC3

- IC2 pin 2 connects to (+) supply

- IC2 pin 3 connects to GND

- IC2 pin 4 connects to pin 1 of IC1

- IC3 pin 1 connects to capacitor C4

- Anode of IC3 connects to 0V GND

- Cathode of IC3 connects to pin 1 of IC2

- Transformer Leg 1 of primary side connects to 230V AC live

- Transformer Leg 2 connects to pin 4 of IC1

- Transformer Leg 3 connects to GND 0V

- Transformer Leg 4 go to secondary side of 12V DC

- Transformer Negative leg connects to GND

- Transformer Positive leg connects to 230V AC live

- Other 2 legs connects to AC power input L and N

Conclusion:

Making 12V SMPS Driver Circuit for LED Strip is good and useful project.

It works better than linear regulators and saves more power and makes less heat.

But be careful with high voltage is dangerous.

Always unplug before touching any parts, work in good light and ask expert if unsure about electronics.

Start with small low voltage projects first.

Leave a Reply