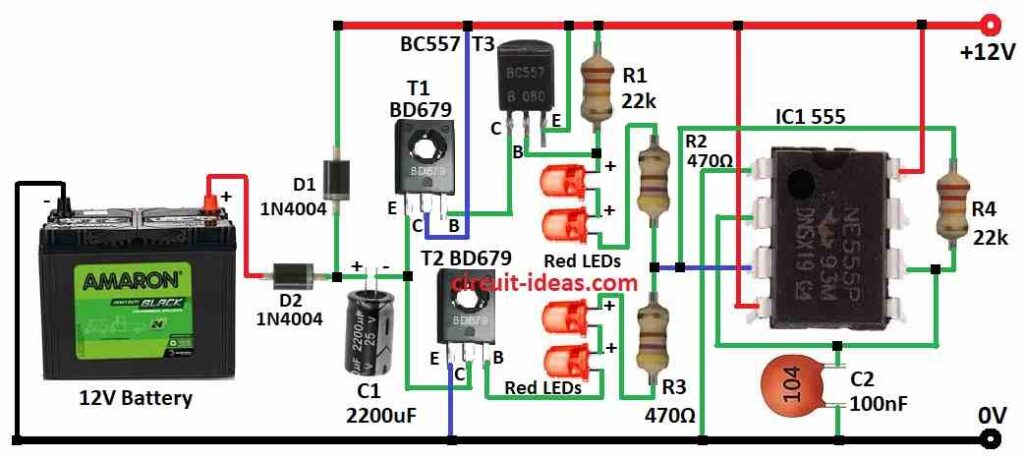

In this post for How to Charge a 12V Battery from a 12V Supply, this circuit uses 12V power and work like battery charger.

It make voltage go higher than 12V to push current into battery.

It uses special parts and control transistors good so there is no overheat.

It give safe charging current around 900mA and even if voltage is not full upto 12V.

We need to remember battery size, follow charge time and some power lost during charging.

Circuit Working:

Parts List:

| Category | Description | Quantity |

|---|---|---|

| Resistors | 22k, 470Ω 1/4 watt | 2 each |

| Capacitors | Ceramic 100nF | 1 |

| Electrolytic 2200μF 25V | 1 | |

| Semiconductors | IC 555 | 1 |

| Transistor BD679 | 2 | |

| Transistor BC557 | 1 | |

| LEDs Red 5mm 20mA | 4 | |

| Diode 1N4004 | 2 | |

| Battery 12V | 1 |

12V battery can not charge another 12V battery.

Charging stops when battery voltage equals charger voltage.

This circuit uses charge pump to make voltage more than 12V for charging.

Diodes and transistors need heatsinks and this circuit gives around 900mA charging current.

LEDs stop both output transistors from turning on together.

Bottom transistor turns on after 5Vand top one after 4V.

Only when voltage cross 4V middle gap then they switch.

This switch happens very fast and no current goes through both at same time.

D2 diode and T2 transistor help charge electrolytic capacitor up to 10V.

T1 transistor give 900mA current and it pulls C1 capacitors negative to 12V supply so positive goes up to around 21V (12V + 9V).

This energy go through D2 to battery.

Battery should charge slowly and not more than 14 hour rate.

Example: 17AHr battery must charge at 1.2A or less (17 ÷ 14 = 1.2A).

Use smaller capacitor with 1000uF for small batteries.

80% of charge is efficient so need of 120% of battery AHr to fully charge.

Formulas:

We can make simple charger using IC 555 and some extra parts to charge 12V battery from 12V source.

This is basic idea diagram and we used formula below to find charging current:

Charging Current (Icharge) = (Vsupply − Vbattery) / Rcharge

where,

- Vsupply is 12V.

- Vbattery starts near 12V which goes higher while charging.

- Rcharge is total resistance in charging path.

Control charging current to stop battery from overheat or damage.

Make sure resistors and transistors handle current.

Use formula:

Power = I² × R

Add heatsinks if needed.

Better to follow tested circuit designs or read IC 555 battery charger datasheet.

Charging circuits can be risky so always use safety steps.

Safety Tips:

- Use heatsinks to stop parts from overheating.

- Check input voltage is correct.

- Be sure all wires and soldering are correct before power ON.

- Watch circuit while running and especially first time to find any problems.

Conclusion:

This circuit can charge 12V battery from 12V supply with no higher voltage needed.

But always use heatsinks, right parts and safe charging methods.

Be careful while using.

References:

What happens if a 12V battery is constantly exposed to a 12V power supply?

Leave a Reply