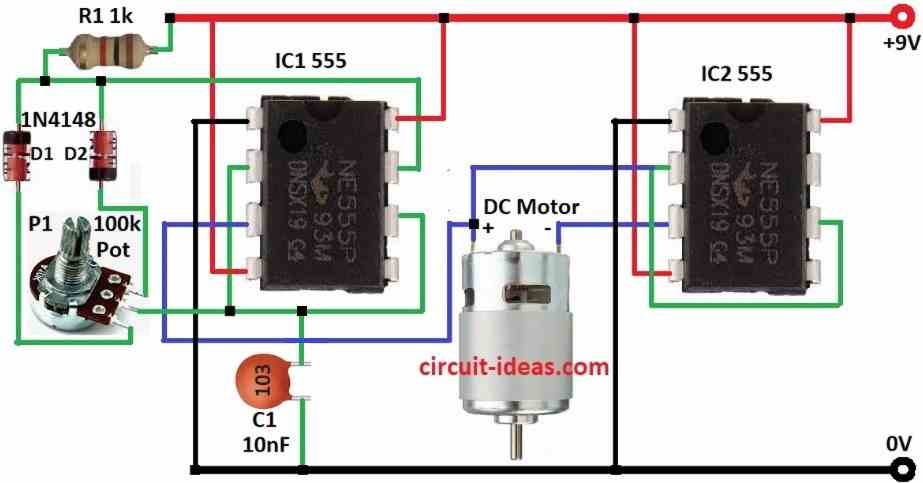

H-Bridge PWM Driver Circuit using IC 555 controls DC motor speed and direction.

In this circuit no driver transistors are used.

Motor connect direct to two IC 555.

Motor speed and direction can change.

We can only use two IC 555 to control the motor.

This circuit is easy to make and is used for small motor projects.

Circuit Working:

Parts List:

| Category | Description | Quantity |

|---|---|---|

| Resistor | 1k 1/4 watt | 1 |

| Potentiometer 100k | 1 | |

| Capacitor | Ceramic 10nF | 1 |

| Semiconductors | IC 555 | 2 |

| Diodes 1N4148 | 2 | |

| DC Motor | 1 |

This circuit uses two IC 555 which is called IC1 and IC2.

IC1 make PWM signal like astable multivibrator.

Pin 3 of IC1 give PWM output.

Speed and signal duty change by R1, C1 and potentiometer which is the variable resistor.

IC2 work like flip-flop (set-reset).

When IC1 pin 3 is high then IC2 pin 2 and pin 6 goes more than 2/3 VCC.

Then IC2 pin 3 goes low and motor turns clockwise.

When IC1 pin 3 is low then IC2 pin 2 and pin 6 goes less than 1/3 VCC and then IC2 pin 3 goes high and motor turn anti-clockwise.

Turning pot changes resistance and this changes C1 charge/discharge time.

That change PWM duty cycle.

Motor is load and H-bridge setup control motor speed and direction.

Motor move clockwise or anti-clockwise by ON/OFF signal from IC1.

IC1 give PWM and duty cycle decide motor speed.

Change potentiometer to adjust duty cycle.

Circuit run with 9V battery or power supply.

Formulas:

To control H-Bridge switch or DC motor speed we need to use IC 555 in astable mode and this makes PWM signal.

Below is formula:

Frequency (f):

How fast it switches depends on resistor R1, R2 and capacitor C.

Formula:

f = 1.44 / (R1 + 2R2) × C

- R1 and R2 connect to IC 555

- C is timing capacitor

Duty Cycle D:

Duty cycle mean how long output stay ON vs OFF.

Formula:

D = R2 / (R1 + 2R2)

Use this to make PWM signal for H-Bridge driver and this controls motor speed and direction.

How to Build:

To build a H-Bridge PWM Driver Circuit using IC 555 follow the below mentioned connections steps:

- Take all parts as shown in diagram.

- Connect pin 1 of IC1 to ground.

- Connect pin 2 and pin 6 of IC1 together.

- Connect pin 3 of IC1 to positive side of DC motor.

- Connect pin 4 of IC1 to 9V power.

- Connect pin 6 of IC1 again to pin 2.

- Connect pin 7 of IC1 to two diodes D1 and D2.

- Connect pin 8 of IC1 to 9V supply.

- Put capacitor C1 from pin 2/pin 6 to ground.

- Connect middle leg of Pot P1 to pin 2/pin 6 of IC1.

- Connect 1st and 3rd leg of Pot P1 to each diode.

- Put resistor R1 between diodes D1 and D2 to 9V supply.

Connection of IC2 555:

- Pin 1 of IC2 go to ground.

- Connect pin 2 and pin 6 of IC2 together.

- Connect pin 3 of IC2 to negative side of DC motor.

- Connect pin 4 of IC2 to 9V supply.

- Connect pin 6 again to pin 2.

- Connect pin 8 of IC2 to 9V supply.

Conclusion:

This H-Bridge PWM Driver Circuit using IC 555 control DC motor speed and direction using H-bridge and IC 555 PWM.

It have some small problem in smooth direction change and current handling but it is good for learning.

For big motors or strong work better use special H-bridge driver IC.

References:

H-Bridge: forward and backward dc motor with ic 555 by esp8266 gpio

Leave a Reply