CFL bulb need special helper circuit to turn ON and glow bright.

This Simple CFL Driver Circuit change home electricity into power CFL can use.

CFL bulb uses little mercury vapor to make invisible light.

Then it hits special powder to make light we see.

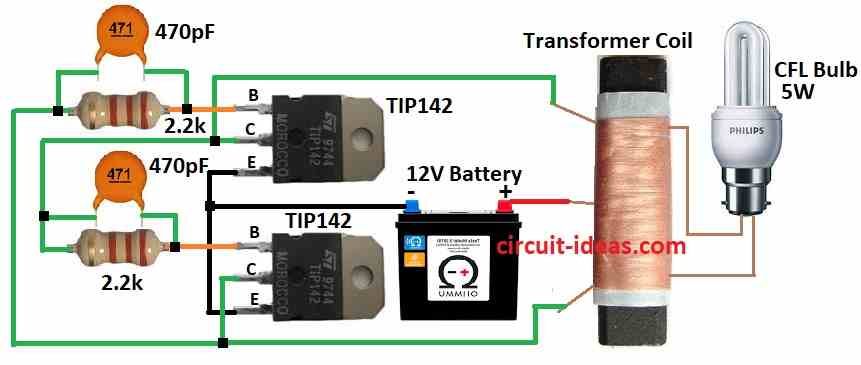

Circuit Working:

Parts List:

| Category | Item | Quantity |

|---|---|---|

| Resistors (All resistors are assumed to be 1/4 watt) | 2.2k | 2 |

| Capacitors | Ceramic 470pF | 2 |

| Semiconductors | Transistors TIP142 | 2 |

| Transformer Coil see the text | 1 | |

| CFL Bulb 5W | 1 | |

| Battery 12V | 1 |

Two TIP142 transistors are NPN Darlington type and they can handle big current.

They connect in cross way with base of one goes to collector of other with 2.2k resistor.

This design make one transistor turn OFF when other is ON like push-pull.

Transformer has center tap and its outer wires go to transistor collectors.

Center tap goes to battery positive and emitters goes to battery negative.

This way transistors switch current in transformer and make changing magnetic field.

When one transistor is ON, current flow make magnetic field one way.

It creates voltage in secondary and light up CFL.

Then other transistor turns ON and current goes the other way.

And with this the magnetic field flip and AC keeps flowing.

CFL connect to secondary side and AC in coil light up the CFL.

Whole circuit works good with high efficiency and with low power use.

Working of Transformer:

This circuit run 5W CFL using 12V power.

Transformer made by winding 50 turns which then make center tap.

Another 50 turns added for push-pull primary.

Use ferrite rod with round or flat from old AM radio for core.

Secondary winding need 500 turns.

Wind carefully one layer over other and moving along the rod with no overlap.

This way is called a jumble winding, wire enamel hold only 100V.

Use thin wire with 0.25mm or smaller.

Before winding put 3 layers of sticky tape on rod to stop high voltage short.

How to Build:

To build a Simple CFL Driver Circuit we need to follow the below mentioned steps:

- Get all parts shown in diagram.

- Join two transistors in cross way.

- Base of first goes to collector of second with 2.2k resistor.

- Same for other side.

- Connect both emitters together.

- Transformer has center tap.

- Connect outer primary wires to transistor collectors.

- Center tap goes to battery positive.

- Emitters goes to battery negative.

- Connect secondary side of transformer to CFL lamp.

- Be sure wires are safe and tight.

Test Circuit:

- Before final setup test the circuit.

- Check if transistors switch and CFL lights.

- Be careful and use safety steps.

Final Setup:

- If test OK then fix all wires and cover open parts.

- High voltage is risky.

- If not sure ask expert or take help.

Conclusion:

In this Simple CFL Driver Circuit it changes power to right form for CFL.

It boost voltage and gives right current and makes CFL work safe and good.

It is good for saving energy.

References:

General circuit diagram pattern for the CFL electronic ballast.

Leave a Reply