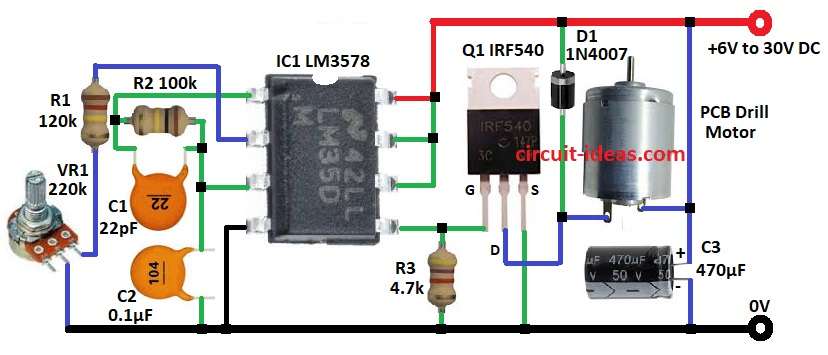

This tutorial is about Motor Speed Regulator Circuit for PCB Drills

It control speed for clean and accurate holes.

Main part of the circuit is LM3578 IC with feedback and 1V reference.

It also has oscillator.

LM3578 and IRF540 MOSFET adjust motor speed.

They give smooth, adjustable speed for small PCB drills.

Supply is from 6 to 30V DC but it should match the motor voltage.

Circuit Working:

Parts List:

| Component Type | Value/Part Number | Quantity |

|---|---|---|

| Resistors (All resistors are 1/4 watt unless specified) | 120k | 1 |

| 100k | 1 | |

| 4.7k | 1 | |

| Potentiometer 220k | 1 | |

| Capacitors | Ceramic 22pF | 1 |

| Ceramic 0.1µF | 1 | |

| Electrolytic 470µF 50V | 1 | |

| Semiconductors | IC LM3578 | 1 |

| MOSFET IRF540 | 1 | |

| Diode 1N4007 | 1 | |

| PCB Drill Motor | 1 |

Circuit uses LM3578 switching regulator to make PWM for motor speed.

MOSFET IRF540 works as switch and controls power to motor.

R1, R2, VR1 set reference voltage and work with C1 to set oscillator frequency.

C2 gives stability.

LM3578 IC makes PWM from feedback.

IRF540 switches fast and controls motor power.

D1 diode stops damage from back EMF.

VR1 potentiometer lets us adjust motor speed.

C3 filters supply for smooth and reliable work.

R3 pulls MOSFET gate low when LM3578 output is low and avoids floating issues.

Formulas with Calculations:

Below are the formulas with calculations for Simple Motor Speed Regulator Circuit for PCB Drills:

Formula for LM3578 oscillation:

f = 1 / (R3 × C1 × 1.3)

here,

R3 = 100k and C1 = 22pF

f = 1 / (100k × 22pF × 1.3) = 348 kHz

Duty cycle set by feedback and resistor network controls the motor speed.

How to Build:

To build a Simple Motor Speed Regulator Circuit for PCB Drills following steps are required to follow:

- Put all parts on PCB ad per diagram.

- Pin1 of IC to join of R2 end and C1 end.

- Pin2 of IC goes to one end of R1 and other R1 end to VR1 and other VR1 end goes to GND.

- Pin3 of IC goes to other end of R2 and other end of C1.

- C2 goes from pin3 to GND.

- Pin4 of IC goes to GND.

- Pin5 of IC connect to GATE of Q1 MOSFET.

- R3 from pin5 go to GND which is pull-down.

- Pin 6,7,8 of IC go to +V of 6 to 30V DC.

- Drill motor positive goes to +V, and motor other wire go to DRAIN of Q1.

- D1 diode from +V go to motor/Drain area which is protect from back EMF.

- SOURCE of Q1 go to GND.

- C3 positive go to +V and C3 negative go to GND which is supply filter.

Conclusion:

Motor Speed Regulator Circuit for PCB Drills are easy and simple.

It uses LM3578 PWM and IRF540 switch.

The circuit smooth adjustable speed with low heat and is quite efficient.

It picks supply voltage from 6 to 30V to match motor.

Leave a Reply